Thermal cameras are essential tools in security, construction, and medical diagnostics, providing visibility in low light, smoke, or fog by detecting infrared radiation instead of visible light. But why are they so expensive? The answer lies in the advanced thermal imaging technology behind them—specifically the lens, infrared detectors, electronics, and image processing algorithms—all of which contribute to higher production costs compared to visible light cameras.

1. Infrared Lenses: Costly but Critical

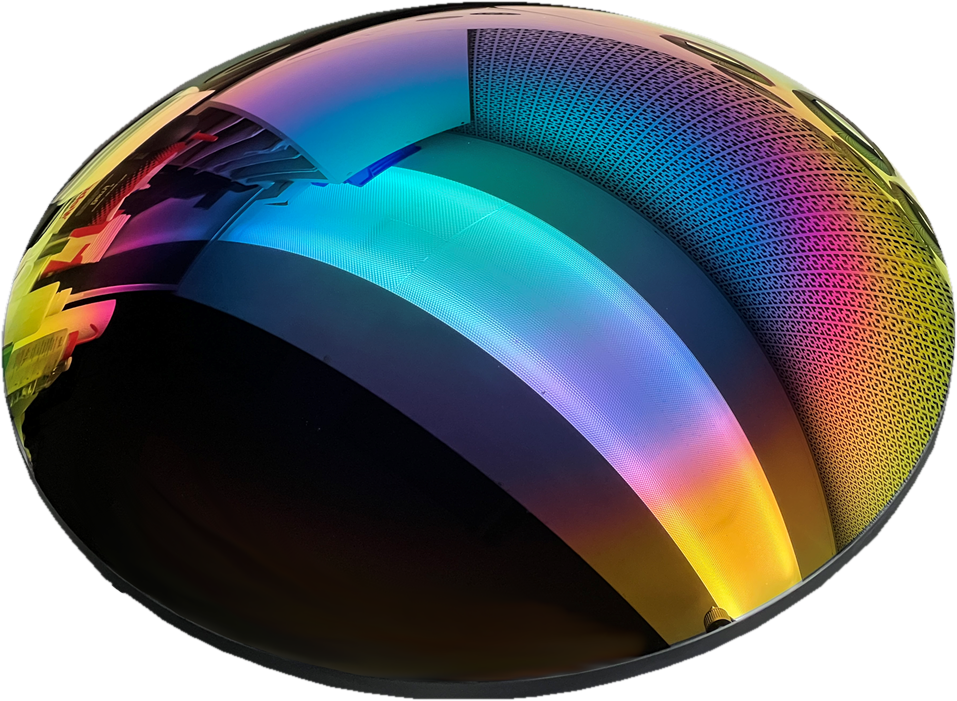

Thermal imaging cameras use lenses made from specialized materials like Germanium, Silicon, Zinc Sulphide, Zinc Selenide and Chalcogenides. Optical glasses are relatively inexpensive as they are comprised of abundant materials such as silica (a major component of sand). Germanium and Silicon, by contrast are semiconductors which are transparent to infrared light. Semiconductor materials must be mined and then grown into monocrystalline, optical grade crystals. This is a complex specialized and costly process. To ensure the maximum optical performance, the silicon and germanium must be doped to exacting limits.

Zinc sulfide (ZnS) and Zinc selenide (ZnSe) are manufactured by a process called chemical vapor deposition (CVD). CVD material growth is another very specialized process, mastered by only a few companies around the world. To ensure the maximum transparency, some materials need to undergo an additional process called 'hipping' or Hot Isostatic Pressure. This process removes impurities and scattering centers to increase the transmission of infrared light.

A third class of infrared materials are the chalcogenide glasses. Chalcogenides are a glassy mixture of typically germanium arsenic and selenium, although other combinations are sometimes used. Chalcogenides are manufactured in a way more similar to high precision optical glasses, but smaller batch quantities and stringent process controls make these materials comparable in cost to CVD materials. All infrared materials require advanced technology to realize the required levels of performance.

Semiconductor, CVD and Chalcogenide infrared glasses all transmit over the infrared spectrum and are used to make thermal lenses allowing accurate detection of heat signatures and infrared emissions. For longwave infrared (LWIR) cameras, Germanium remains the material of choice as it offers unparalleled performance due to its high refractive index and low dispersion, enabling the best image quality. Germanium glass is used abundantly for uncooled thermal cameras and other thermal devices. However, germanium is rare, with minimal natural deposits, raising material cost making these specialized materials expensive to process.

In the mid-wave infrared (MWIR), Silicon is used more extensively, often with Germanium, Zinc Selenide and Chalcogenide elements to improve image clarity and also performance over temperature.

Lenses for infrared cameras are fabricated using different techniques compared to glass lenses used for visible cameras. Infrared camera lenses frequently incorporate aspheric and diffractive surfaces which are made using a high precision process called diamond turning. A precision lens for visible light cameras may incorporate some aspheric surfaces sparingly, but most optical glass lenses are spherical components which are made using a less expensive CNC or conventional polishing processes.

Custom or large-aperture, long focal length lenses, especially for security cameras or border security systems, further increases the cost of thermal imaging equipment. In some cases, the lens alone can cost more than the infrared detector itself.

2. Infrared Detectors: The Heart of the System

Infrared detectors are divided into cooled and uncooled categories.

Cryogenically Cooled Infrared Photon Detectors

Cooled infrared detectors are used in high-end defense and scientific thermal imaging devices, they are photon detectors and require cryogenic coolers to operate below 80K (193 Deg C), driving up cost and complexity. Uncooled infrared detectors operate at ambient temperature so do not have the costs associated with the cryogenic cooling.

Uncooled Infrared Detectors

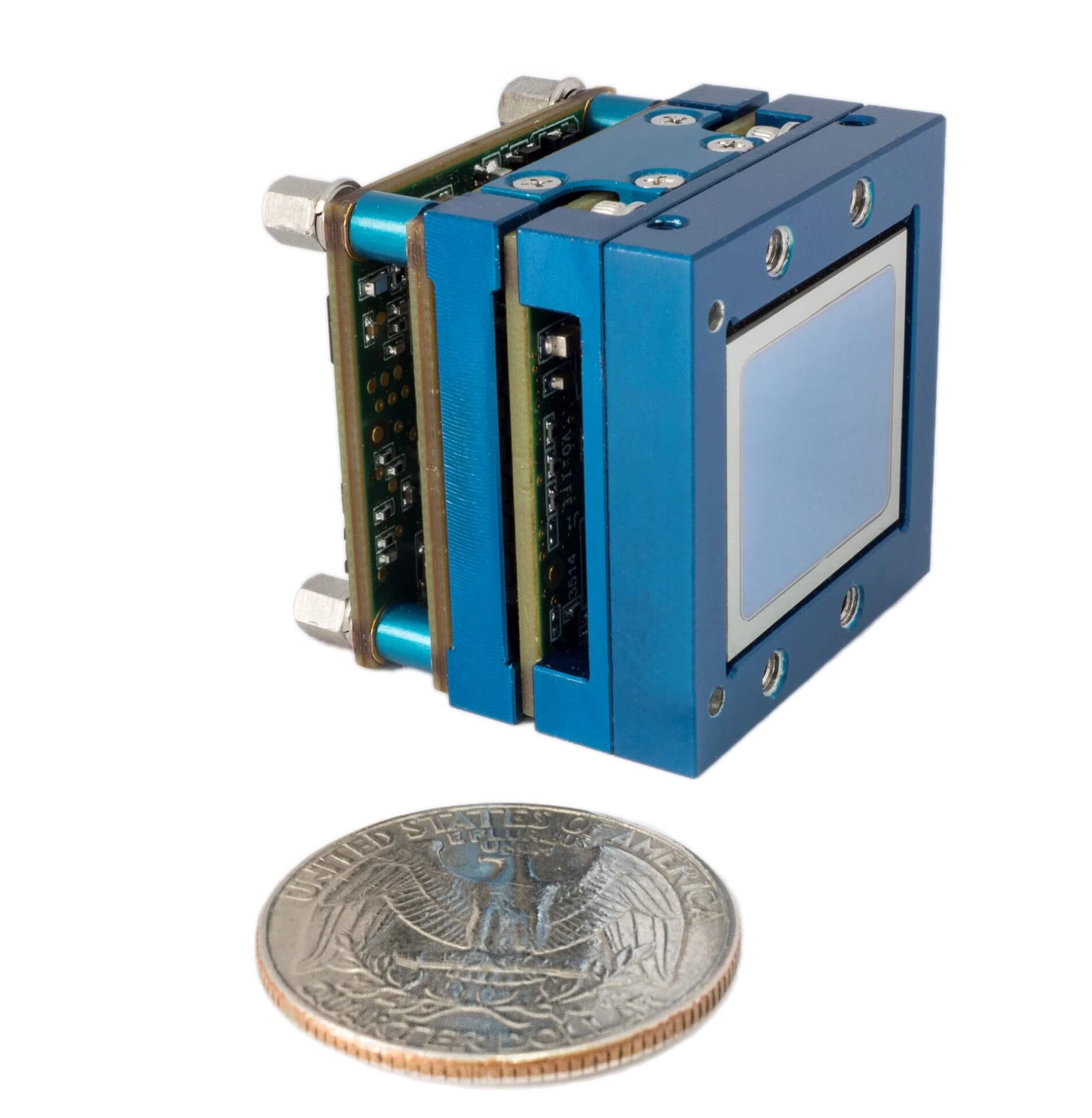

Most commercial thermal cameras use uncooled thermal detectors, using sensors made from Amorphous silicon, Titanium oxide or Vanadium oxide materials. These sensors are classed as bolometers as they which convert infrared energy directly into electrical signals through their change in resistance. Fabrication of these sensors used highly advanced technology which is often not compatible with CMOS processes used for ordinary cameras. Vanadium oxide offers the best thermal sensitivity, typically less than 25 mK (F/1, 30 Hz), giving better temperature measurement accuracy, but costs roughly 200 times more than a silicon-based CMOS sensor used in regular visible camera system.

Higher Definition Infrared Detectors

Higher-resolution, higher definition thermal imaging sensors, like those with 1280x1024 or even 2560x2048 pixels, significantly boost performance but at a higher cost. The higher the resolution, the larger the area of the wafer that is used and the higher the probability of manufacturing defects and rejects. Larger format specialized sensors are significantly more expensive (2-5x) the cost of lower resolution sensors. But for critical applications such as airborne intelligence, Surveillance and reconnaissance, long range border surveillance this capability is critical. This is a key aspect of what makes infrared cameras so expensive.

3. Video Electronics: Design and Calibration

The video electronics in thermal imaging cameras are a key differentiator between thermal cameras and regular cameras. Because thermal cameras are measuring infrared light rather than visible light, they require more advanced calibration over temperature and more sophisticated image processing embedded in the circuit board FPGA. Most thermal imaging cameras use shutter-based calibration systems that enables the thermal sensor to be calibrated for a given scene and ambient temperature.

Another challenge is integrating the focal plane array into the thermal camera as this requires micron-level precision with complex thermal management of the circuit board and vibration isolation for rugged real-world use.

Advanced Image Processing Algorithms: Higher Value Add

Thermal imaging cameras require advanced image processing techniques as infrared radiation is less abundant than visible light. Tailored algorithms are essential for applications with different temperature measurement needs (e.g., -20°C to 600°C), affecting resolution and thermal radiation contrast. This customization increases both software development costs and the final cost of thermal imaging equipment.

Artificial Intelligence (AI) classification and tracking algorithms are now embedded into the most thermal camera models. The heat signatures

For specialized security applications, such as detecting concealed weapons, classifying humans or small drones (sUAS), advanced algorithms provide actionable information and ensure thermal imaging cameras maintain performance regardless of environmental conditions.

5. Other Cost Factors

a. Functionality

Modern thermal cameras include networking, video recording, and video analytics. High-end thermal imaging systems used in industrial inspection or defense often support real-time analytics, multiple temperature measurement zones, motion tracking and advanced diagnostics.

b. Frame Rate

Frame rates between 25–60 Hz allow thermal imaging cameras to capture smooth video and track movement accurately. Lower frame rates limit use in motion-heavy environments. Higher frame rates (> 100 Hz) are used for fast event detection such as hostile fire or process control. Operating at higher frame rate increases the data rates which adds cost to the electronics.

c. Brand and Support

Top thermal technology brands offer robust support, long-term software updates, and enhanced quality control—key benefits reflected in their higher price tags.

Conclusion

The higher cost of thermal cameras is the result of multiple factors: rare and exotic materials like germanium glass, technologically advanced infrared sensors, powerful image processing algorithms, and the precision manufacturing process that ties it all together. Unlike visible light cameras, these systems are built to provide a resolve minute levels of thermal radiation, essential for applications in total darkness and degraded visual environments.

Though the cost of thermal imaging remains high, the performance, durability, and versatility of thermal imaging cameras make them a smart investment—especially for users who demand accuracy, reliability, and advanced thermal imaging capabilities. Whether you’re using the first thermal camera for learning or deploying a cutting-edge system for border security, thermal cameras remain an indispensable tool in modern technology.

Bonus Insight:

The earliest known thermal images date back to 1800, when Sir William Herschel discovered invisible light—which we now call infrared radiation—paving the way for today’s advanced thermal imaging cameras.