What Is a Thermal Imaging Camera? How Does It Work?

A Simple Introduction to Thermal Imaging & Thermal Imagers

A thermal imaging camera—sometimes called an IR camera or infrared camera—isn’t your typical gadget. Instead of relying on visible light or what engineers call the visible spectrum like your smartphone or a digital SLR, a thermal imaging device detects infrared radiation or heat. All objects with a temperature above absolute zero radiate infrared radiation, it is not visible to the naked eye or a regular camera, but thermal imaging cameras see it.

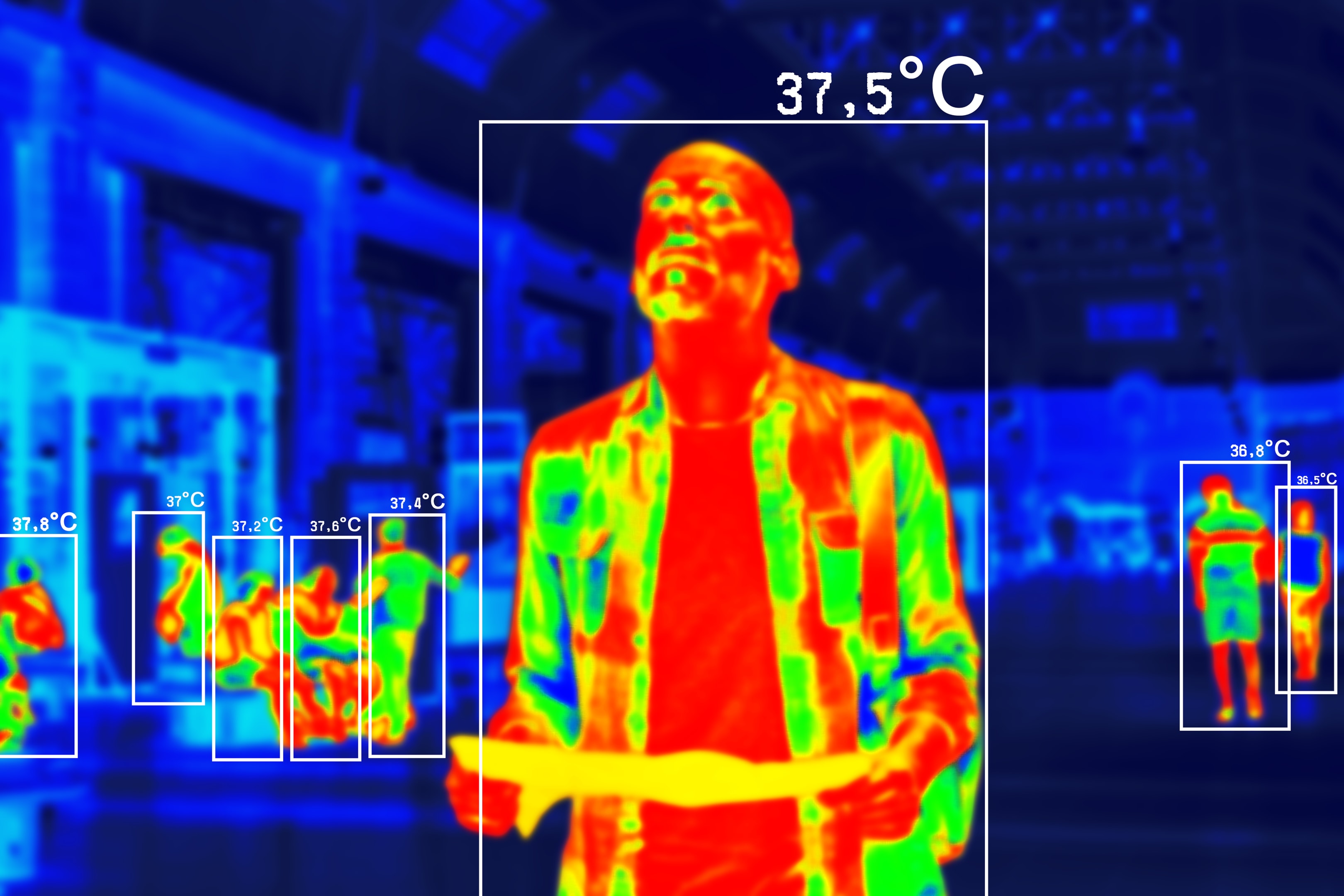

Thermal imaging systems convert invisible heat signatures into colorful images, giving you a real-time view of temperature variations and temperature differences. This makes them essential in defense, industrial inspection, and safety applications. You can see in complete darkness, through smoke or fog, and even detect problems hidden inside electrical and mechanical systems long before they become failures.

The Science Behind Infrared Technology to Measure Temperature Variations

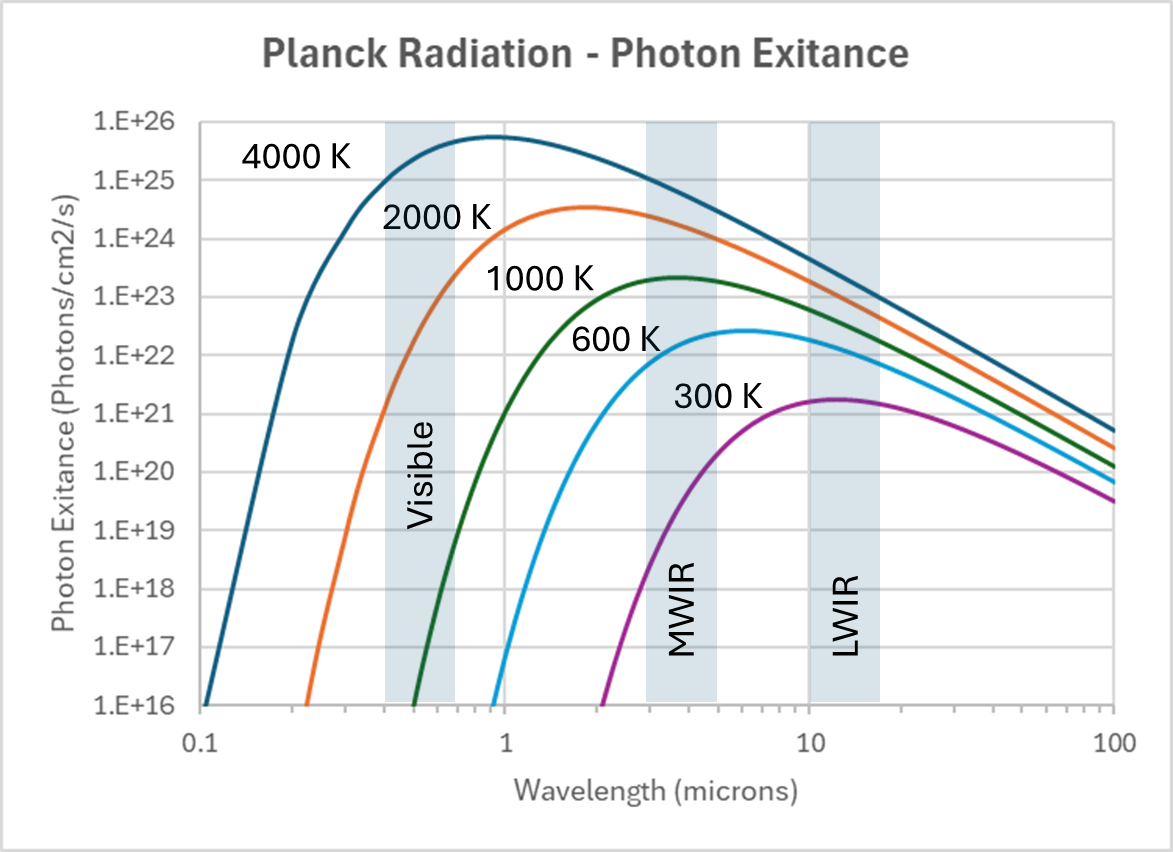

The electromagnetic spectrum contains all wavelengths of 'light' including ultraviolet, visible and thermal radiation. The infrared portion of the spectrum is often called infrared radiation. The amount of thermal energy radiated by an object is determined by the absolute temperature and emissivity of that object. Unlike the visible range of the spectrum, thermal electromagnetic radiation is invisible to the naked eye - it can be thought of as invisible light. In practice, the infrared light is really heat so we detect heat signatures from the scene when we use a thermal camera.

Here’s the science made simple:

-

Infrared Radiation: All objects emit thermal radiation. Hotter objects emit more infrared energy than cooler ones.

-

Sensor Magic: Infrared sensors and specialized optics collect infrared energy and direct it to a focal plane array (FPA).

-

Data Conversion: The FPA translates this detected infrared radiation into an electrical signal for each pixel.

-

Visible Image: Embedded processors turn these signals into a visible image—a thermal “heat map” that clearly shows hot objects in warm colors and cooler areas in blues and purples.

-

No Illumination Needed: Unlike night vision, thermal imaging works in total darkness because it senses thermal radiation emitted naturally, rather than reflected light.

How Infrared Cameras Actually Work – The Core of Thermal Imaging Systems

Let’s break it down step by step:

-

Object: The object emits infrared according to its temperature, heat signature and Planck's Radiation Law.

-

Collect Thermal Energy: The camera optics collect the infrared radiation and focus this energy onto on an infrared detector.

-

Measure Radiation Emitted: The FPA sensor detects this collected radiation as either a change in resistance or voltage and this signal is converted into a precise temperature data pixel by pixel.

-

Process the Signal: Advanced algorithms calibrate and apply false-color mapping to highlight temperature differences.

-

Display the Image: A clear, high-contrast image reveals heat signatures in real time.

This process makes thermal cameras a go-to tool for operators who need to “see” what’s invisible.

Applications of Thermal Imaging

Thermal imagers are used everywhere—from military installations to energy audits:

-

Defense & Border Security: Fixed towers, thermal imaging systems for counter-UAS missions, and mobile surveillance units.

-

Industrial Maintenance: Identifying overheating components in electrical systems or detecting leaks in mechanical systems.

-

Firefighting: Detecting people trapped in a fire through smoke.

-

Search and Rescue: Search and rescue operations for finding people at night or in low visibility conditions.

-

Energy Efficiency: Detecting poor insulation and air leaks to save energy.

Types of Thermal Imaging Cameras

-

Uncooled Cameras

-

Operate at ambient temperature, making them rugged, reliable, and cost-effective.

-

Uncooled microbolometers measure the change in electrical resistance based on the level incident infrared.

-

Cooled Cameras

-

Cooled photodetectors require cooling to minimize thermal noise. The cryogenic coolers dramatically improve thermal sensitivity, enabling the benefit of high resolution to be realized for long-range detection.

-

Several types of sensor material are used including mercury cadmium telluride, indium antimonide and strained superlattices.

-

Platform Types:

-

Handheld imaging cameras for inspections

-

Fixed-site thermal imaging systems for perimeter security

-

Drone and vehicle-mounted platforms for mobile surveillance

Thermography: Turning Heat into Insight

Thermography is the science of turning infrared radiation emitted by surfaces into actionable intelligence.

-

Passive Thermography: Relies solely on heat emitted by objects. The thermal camera is calibrated to measure absolute temperature values just by pointing the camera at the object.

-

Active Thermography: Adds additional external heat to reveal subsurface flaws. Thermal anomalies can also be more accurately detected.

-

Thermographic cameras are non-invasive tools that let you “see” structural and electrical issues without taking anything apart.

Choosing the Right Imaging Camera

-

Resolution: Higher resolution = sharper infrared imaging n.

-

Sensitivity: Determines how small a temperature difference the thermal imaging device can detect.

-

Field of View: Wide FOV for large area scans, narrow FOV for distant targets.

-

Integration: Advanced thermal imaging systems now link to AI analytics and other sensors.

-

Platform Fit: Choose thermal cameras based on your environment—handheld, fixed, or robotic.

Limitations of Thermal Imaging Cameras

Even cutting-edge infrared cameras have boundaries:

-

Can’t see through walls or glass.

-

Accuracy is affected by emissivity, reflectivity, and ambient temperature.

-

High-performance cooled systems cost a little more.

-

Heavy rain, fog, or snow can reduce performance, particularly in the long wave infrared.

The Future of Thermal Imaging Cameras

The next generation of thermal imaging cameras will be:

-

AI-driven: Automated detection of thermal signatures in complex environments.

-

Smaller and Lighter: Easier to mount on drones, vehicles, and autonomous robots.

-

More Affordable: Bringing advanced infrared technology to more industries.

-

Smarter: Integrating infrared detectors with cloud data analytics for predictive maintenance.

Maintenance and Best Practices

To ensure accurate temperature readings:

-

Clean and calibrate your thermal imaging devices often.

-

Train teams to interpret infrared cameras work correctly.

-

Update software for better image processing.

Conclusion

A thermal imaging camera transforms invisible infrared rays into actionable intelligence, making it a non-contact temperature measurement powerhouse. From defense and surveillance to predictive maintenance and energy audits, thermal cameras work as your eyes in the infrared spectrum.

With ongoing innovation, thermal imaging devices are becoming lighter, smarter, and more accessible, making them a cornerstone technology for industries that need early detection of problems and enhanced situational awareness.