Why Are Thermal Cameras So Expensive?

Thermal cameras, also called Infrared cameras, are essential tools in security, construction, and medical diagnostics, providing visibility in low light, smoke, or fog by detecting infrared radiation instead of visible light.

But why are they so expensive? The answer lies in the advanced thermal imaging technology behind them—specifically the lens, infrared detectors, electronics, and image processing algorithms—all of which contribute to higher production costs compared to visible light cameras.

Thermal cameras require specialized components, which significantly increases their cost. Additionally, market demand for thermal cameras is lower than visible light cameras, which impacts pricing and availability. There are also a notable price difference between various types of thermal cameras, such as those with cooled versus uncooled detectors.

Introduction to Infrared Cameras

Thermal imaging technology has transformed the way we observe and interact with the world around us with unique temperature measurement capability. Unlike visible light cameras, which rely on ambient light to capture images, thermal cameras—also known as thermal imagers—detect infrared radiation naturally emitted by all heat objects. This allows thermal imaging cameras to visualize heat signatures, revealing details that are invisible to the naked eye or to standard cameras.

The journey of thermal imaging began in 1800, when Sir William Herschel discovered thermal radiation, and took a major leap forward with the invention of the first thermal camera in 1929. Since then, thermal imaging technology has advanced rapidly, moving beyond its early military applications to become indispensable in fields such as security, medicine, search and rescue, and even outdoor adventures.

1. Infrared Spectrum Lenses: Costly but Critical

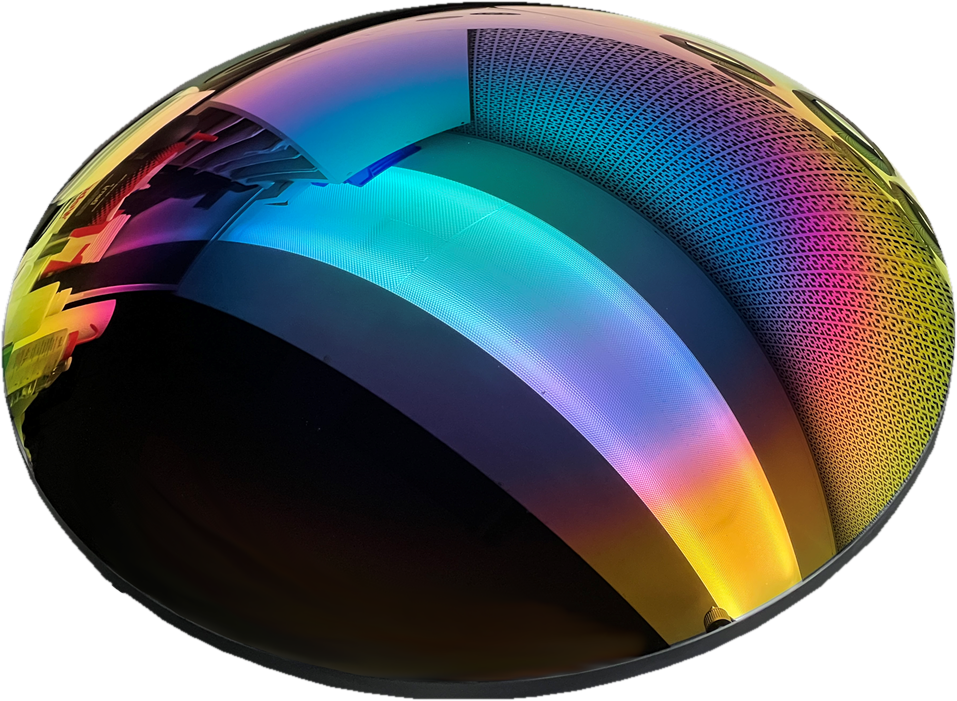

Thermal imaging camera production costs are high, using lenses made from specialized materials like Germanium, Silicon, Zinc Sulphide, Zinc Selenide and Chalcogenides.

Optical glasses are relatively inexpensive as they are comprised of abundant materials such as silica (a major component of sand).

Germanium and Silicon, by contrast are semiconductors which are transparent to infrared light. Semiconductor materials must be mined and then grown into monocrystalline, optical grade crystals. This is a complex specialized process. To ensure the maximum optical performance, the silicon and germanium must be doped to exacting limits.

Germanium is typically grown using the Czochralski method. The result is a high purity boule of germanium. Material is selected according to its ohm resistivity which varies along the boule. Ohm resistivity determines the optical transmission of the material. This highly selective process is one of the reasons that can make infrared cameras so expensive.

Zinc sulfide (ZnS) and Zinc selenide (ZnSe) are manufactured by a process called chemical vapor deposition (CVD). CVD material growth is another very specialized process, mastered by only a few companies around the world. To ensure the maximum transparency, some materials need to undergo an additional process called ‘hipping’ or Hot Isostatic Pressure. This process removes impurities and scattering centers to increase the transmission of infrared light.

Chalcogenides glasses are a glassy mixture of typically germanium arsenic and selenium, although other combinations are sometimes used. Chalcogenides are manufactured in a way more similar to high precision optical glasses, but smaller batch quantities and stringent process controls make these materials comparable in cost to CVD materials.

Semiconductor, CVD and Chalcogenide infrared glasses all transmit over the infrared spectrum and are used to make thermal lenses allowing accurate detection of heat signatures and infrared emissions. For longwave infrared (LWIR) cameras, Germanium offers unparalleled performance due to its high refractive index and low dispersion.However, germanium is rare, with minimal natural deposits, raising material cost. In the mid-wave infrared (MWIR), Silicon, Zinc Selenide and Chalcogenide are alternatives to improve image clarity and performance over temperature.

Infrared camera lenses incorporate aspheric and diffractive surfaces which are made using a high precision process called diamond turning. A precision lens for visible cameras mostly use spherical components that use less expensive CNC or conventional polishing.

Custom or large-aperture, long focal length lenses, especially for infrared cameras or border security systems, further increases the cost of infrared imaging equipment. In some cases, the lens alone can cost more than the infrared detector itself.

2. Infrared Detectors: The Heart of the System

Infrared detectors are divided into cooled and uncooled categories. The choice between cooled and cheaper cameras in the uncooled category can be crucial. The accuracy of temperature measurement has a direct correlation to the temperature of operation of the sensor as there is less noise as temperature is reduced.

Cryogenically Cooled Infrared Photon Detectors

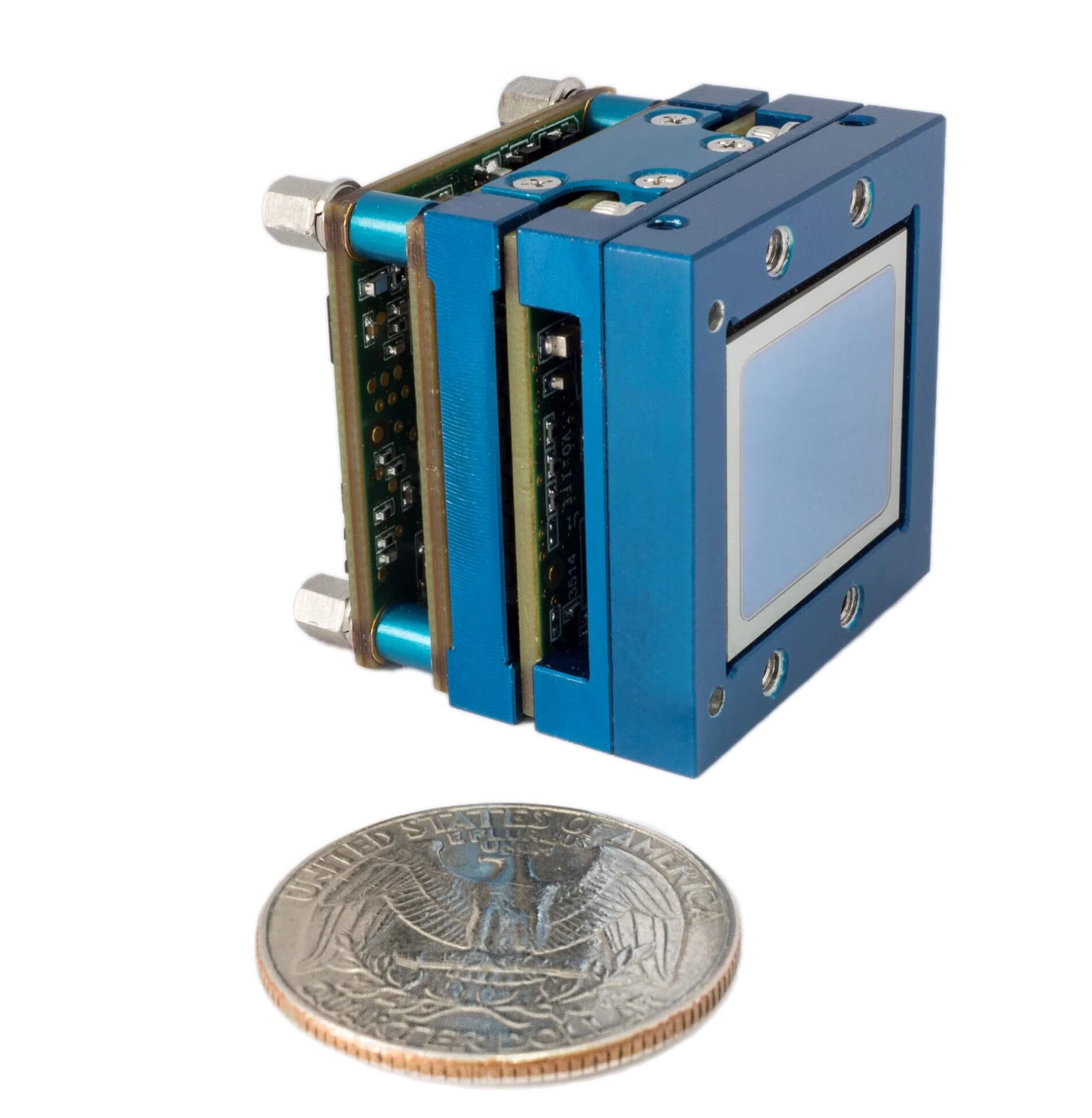

Cooled infrared detectors are used in high-end defense and scientific thermal imaging devices. These photon detectors require a cryogenic cooler, which is essential for reducing noise and increasing sensitivity. For the highest performance thermal imaging systems, the detector may be cooled down to temperatures below 80K (193 Deg C). This requirement drives up cost and due to the high complexity of the cryocooler.

Uncooled Infrared Detectors

Most commercial thermal cameras use uncooled thermal detectors, using sensors made from Amorphous silicon, Titanium oxide or Vanadium oxide materials. These sensors are classed as bolometers as they which convert infrared energy directly into electrical signals through their change in resistance. Fabrication of these sensors used highly advanced technology which is often not compatible with CMOS processes used for ordinary cameras. Vanadium oxide offers the best thermal sensitivity, typically less than 25 mK (F/1, 30 Hz), giving better temperature measurement accuracy, but costs roughly 200 times more than a silicon-based CMOS sensor used in regular visible camera system.

Higher Definition Infrared Detectors

Higher-resolution, higher definition thermal imaging sensors, like those with 1280x1024 or even 2560x2048 pixels, significantly boost performance but at a cost. The higher the resolution, the larger the area of the wafer that is used and the higher the probability of manufacturing defects and rejects. Larger format specialized sensors are significantly more expensive (2-5x) the cost of lower resolution sensors.

3. Video Electronics: Design and Calibration

The video electronics in thermal imaging cameras are a key differentiator between thermal cameras and regular cameras. Because thermal cameras are measuring infrared light rather than visible light, they require more advanced calibration over temperature and more sophisticated image processing embedded in the circuit board FPGA. Most thermal imaging cameras use shutter-based calibration systems that enables the thermal sensor to be calibrated for a given scene and ambient temperature.

Another challenge is integrating the focal plane array into the thermal camera as this requires micron-level precision with complex thermal management of the circuit board and vibration isolation for rugged real-world use. These complex designs can sometimes lead to issues such as picture freeze, where the thermal image temporarily stops updating due to calibration or cooling system limitations.

Advanced Image Processing Algorithms: Higher Value Add

Thermal imaging cameras require advanced image processing techniques as infrared radiation is less abundant than visible light. Tailored algorithms are essential for applications with different temperature measurement needs (e.g., -20°C to 600°C), affecting resolution and thermal radiation contrast.

This customization increases both software development costs and the final cost of infrared imaging equipment. Each camera model requires proprietary algorithms and hardware configurations to optimize image quality and temperature accuracy for specific applications.

These tailored algorithms are designed for each camera to ensure optimal performance.

Artificial Intelligence (AI) classification and tracking algorithms are now embedded into the most thermal camera models. The heat signatures are processed as the thermal camera generates a thermogram—a precise and detailed pattern of temperature distribution—by measuring heat from numerous points across the scene.

For specialized security applications, such as detecting concealed weapons, classifying humans or small drones (sUAS), advanced algorithms provide actionable information and ensure thermal imaging cameras maintain performance regardless of environmental conditions.

Manufacturing Process and Its Impact

The manufacturing process behind thermal cameras is a major factor in their high cost. Producing a thermal imaging camera requires the use of advanced technology and rare, exotic materials such as germanium glass, and amorphous silicon. These specialized materials are not only expensive to source but also demand advance handling and processing operations to achieve the necessary optical and electronic properties.

The assembly of thermal cameras takes place in highly controlled clean room environments to prevent contamination, ensuring that each component meets strict quality standards. Additionally, the integration of thermal sensors often requires built-in cooling systems to minimize noise and maintain imaging quality.

The cost of thermal imaging is also driven by the expense of unique manufacturing materials, skilled labor, and the continued investment in research and development needed to refine these advanced devices. The result is a product that, while costly, delivers unmatched performance and reliability in demanding applications.

5. Other Cost Factors for Thermal Devices

a. Functionality

Modern thermal cameras include networking, video recording, and video analytics. High-end thermal imaging systems used in industrial inspection or defense often support real-time analytics, multiple temperature measurement zones, motion tracking and advanced diagnostics.

Thermal cameras are often integrated into a comprehensive security solution, providing reliable detection and monitoring capabilities. As part of a modern security system, thermal cameras help reduce false alarms and enhance overall safety, especially in low-light or challenging environments.

b. Frame Rate

Frame rates between 25–60 Hz allow thermal imaging cameras to capture smooth video and track movement accurately. Lower frame rates limit use in motion-heavy environments. Higher frame rates (> 100 Hz) are used for fast event detection such as hostile fire or process control. Operating at higher frame rate increases the data rates which adds cost to the electronics.

c. Brand and Support

Top thermal technology brands offer robust support, long-term software updates, and enhanced quality control—key benefits reflected in their higher price tags.

Benefits of Thermal Cameras in Various Industries

Thermal cameras offer a range of benefits across multiple industries, making their high cost a worthwhile investment. In the security sector, thermal cameras provide reliable surveillance in complete darkness, fog, or smoke—conditions where visible cameras and standard security cameras often fail. Their ability to detect heat signatures means they are immune to visual camouflage, allowing them to spot hidden objects or individuals that would otherwise go unnoticed.

In industrial inspections, thermal imaging cameras are invaluable for identifying overheating components in electrical systems and machinery, helping to prevent costly failures and downtime. They can also detect air leaks, insulation gaps, and HVAC inefficiencies, improving energy efficiency and safety in buildings.

The advanced technology and unique materials used in thermal cameras enable them to outperform regular visible light cameras, offering superior detection capabilities and a high return on investment for businesses and organizations that rely on accurate, real-time thermal imaging.

Conclusion - Why are Thermal Cameras so Expensive?

The higher cost of thermal cameras is the result of multiple factors: rare and exotic materials like germanium glass, technologically advanced infrared sensors, powerful image processing algorithms, and the precision manufacturing process that ties it all together. Unlike visible light cameras, these systems are built to provide a resolve minute levels of thermal radiation, essential for applications in total darkness and degraded visual environments.

Though the cost of thermal imaging remains high, the performance, durability, and versatility of thermal cameras make them a smart investment—especially for users who demand accuracy, reliability, and advanced thermal imaging capabilities. Whether you’re using the first thermal camera for learning or deploying a cutting-edge system for border security, thermal cameras remain an indispensable tool in modern technology.

Bonus Insight: The earliest known thermal images date back to 1800, when Sir William Herschel discovered invisible light—which we now call infrared radiation—paving the way for today’s advanced thermal imaging cameras.