Optical Systems Integration

From Design to Production

Complex Optical Systems Design, Prototyping, & Manufacturing

Clear Align offers expertise in designing, prototyping, and manufacturing advanced optical systems. Our team utilizes cutting-edge optical design software to create sophisticated optical engineering solutions. Whether you need …

-

Multi-sensor surveillance systems from requirement to production

-

Soldier thermal weapon sights for a unique sensor

-

Dual-band third-generation FLIR lenses

-

optics or components for missile subsystems

-

Unmanned systems that support multi-channel payloads with multiple sensors

-

Custom optical modules or tailored assemblies

Do you have an Optical Problem? We Provide Optical Solutions

We have the know-how to build advanced imaging or laser solution whether it is a single lens or system. Clear Align is focused on controlling costs while optimizing image clarity delivering environmentally rugged solutions. Our designers create systems using a disciplined, stage-gate development process to ensure reliability. We fabricate our optical lenses and metal for faster delivery.

Optical engineering plays a crucial role in solving complex optical problems, ensuring that our solutions meet the highest standards of performance and reliability.

Our structured approach ensures every critical parameter is addressed from SRR to MRR, accelerating the path to your goals. We have all the optical, mechanical, electrical, and software tools to integrate optics into your application. We provide in-house evaluation for speed.

Systems Integration Approach Optimize SWaP-C

Our focus is on the system’s solution that considers SWaP-C, Size, Weight, Power and Cost. We drive the system architecture by incorporating the US Department of Defense Architecture Framework (DoDAF) and implementing advanced systems modeling techniques, such as structured and object-oriented approaches.

This includes considering light detection, and optimizing diffraction-limited performance, to meet complex system requirements. We offer state-of-the-art solutions with well-defined stage-gated processes, minimizing risks and enhancing the reliability of your optical system.

We use a modular systems architecture for all our electronics designs to avoid component obsolescence issues.

Imaging Systems

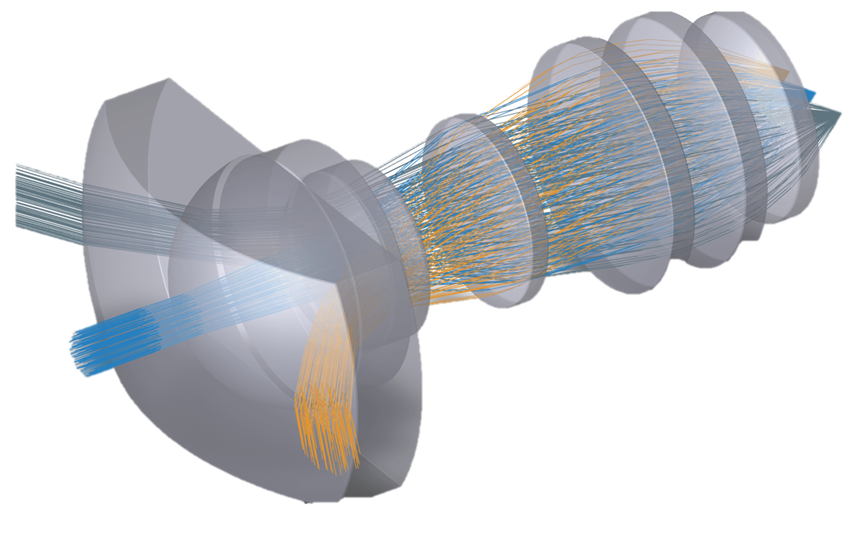

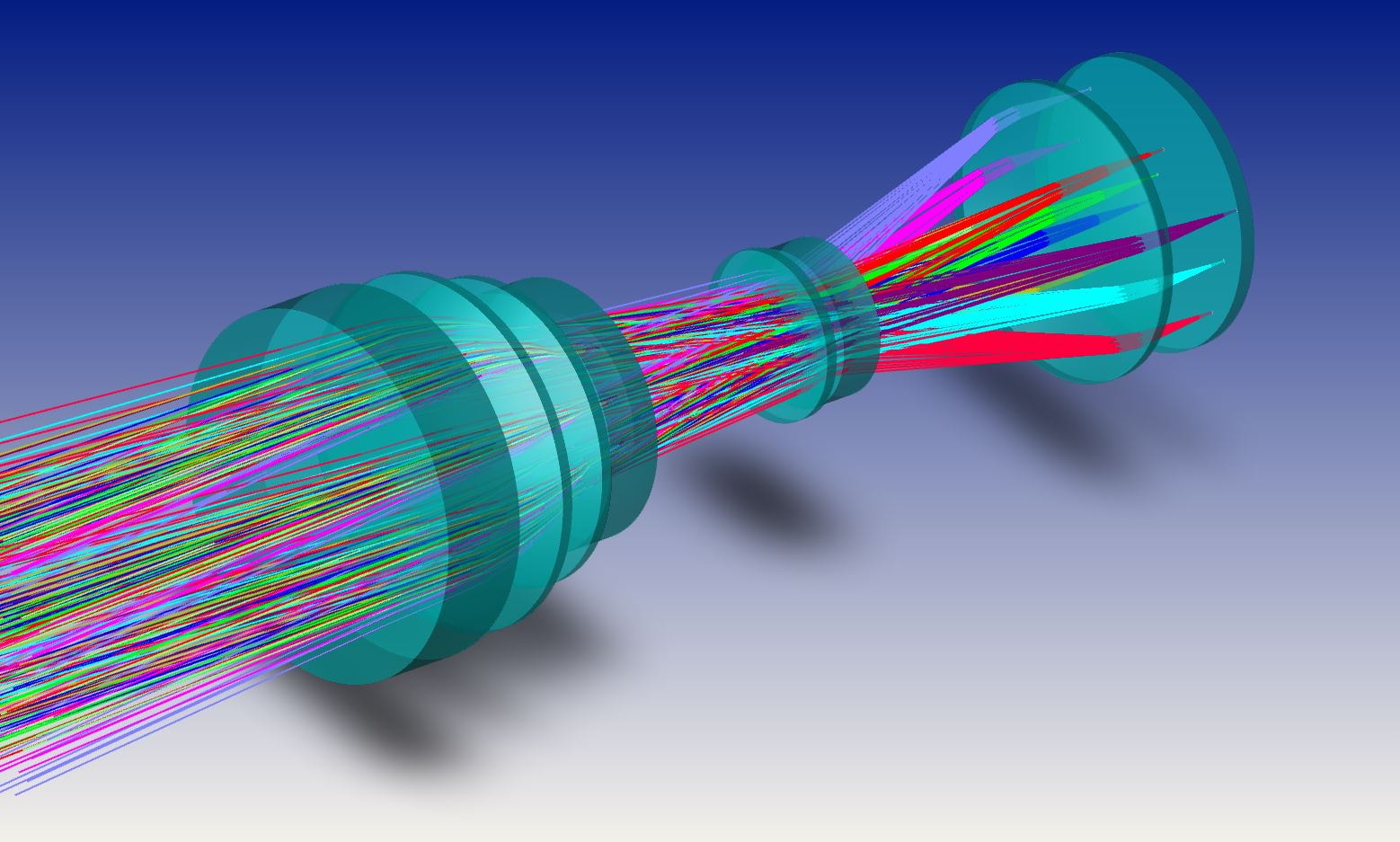

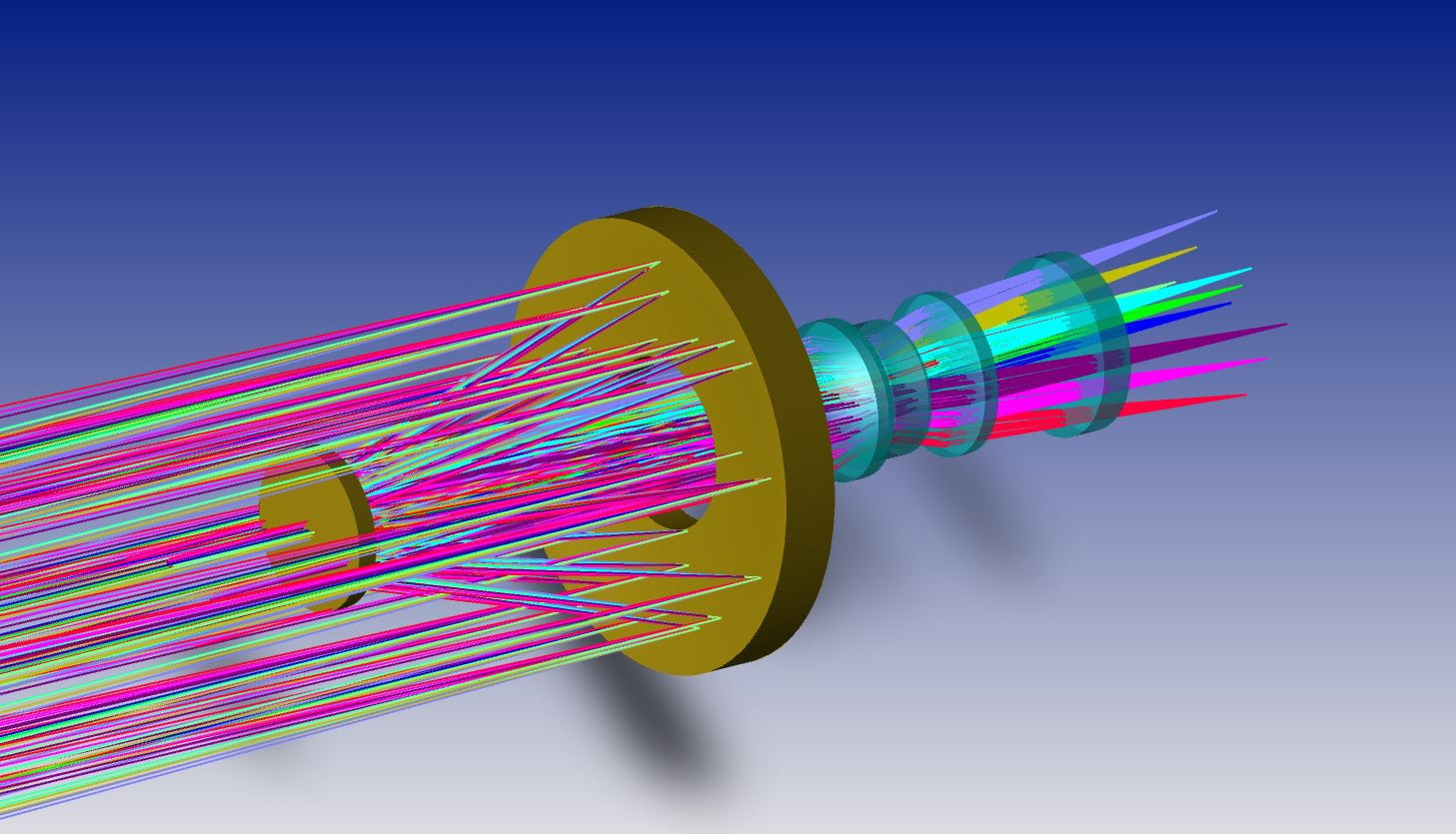

Our optics channel photons to a detector, or an eye, focusing on quality factors such as image clarity, resolution, contrast, and distortion. Optical engineering plays a crucial role in designing high-quality imaging systems with a goal of near diffraction limited performance. Examples include optics for zoom leans, switched field of view, and fixed focal length lenses, modules for laser receivers, and relay systems.

Non-Imaging Systems

Non-imaging systems manipulate light by collecting, dispersing, or focusing it, with performance measured by throughput, field efficiency, spot size, and angular resolution. Optical engineering plays a crucial role in optimizing the performance of these non-imaging systems. Examples include illumination and systems with lasers.

Defining the Application

When embarking on the development of an optical system, the first and most crucial step is defining the application. This involves a thorough understanding of the specific operational needs and requirements of the system. Whether for imaging or non-imaging purposes, it is essential to consider the resolution, sensitivity, and throughput. Additionally, the environmental conditions in which the system will operate, including temperature, humidity, and potential exposure to shock and vibration, must be taken into account. Top designers ensure that optics meet the needs of the end-user.

Establishing System Parameters

Once you’ve identified the system requirements, you can define the primary parameters to guide the design process, ensuring your optical solution meets the specific needs of your application.

Rapid System Deployment with Current Technologies & COTS Integration

Clear Align utilizes modular solutions to quickly transition from development to production ready system. This includes analyzing optical layout, and mechanical housing, and integrating electronics equipment into our EO/IR systems.

Key activities during this phase involve:

-

Requirements analysis, performance analysis, and system design.

-

System integration and verification, requires that our designs incorporate lens elements and retainer rings that keep lenses aligned.

Our method enables quick validation of optical system designs, focusing on both imaging and non-imaging systems while maintaining alignment with performance requirements and application objectives.

Optical Components and Solution Forms

Optical components are the fundamental building blocks of any optical system, and their selection and design are crucial in determining the system’s overall performance. These components can be broadly classified into two categories: active and passive. Active components, such as lasers and light-emitting diodes (LEDs), are sources of light, while passive components, like lenses and mirrors, manipulate and direct the light.

Understanding the interplay between optical components and solution forms is essential for creating custom optical systems that meet specific application requirements. By carefully selecting and designing these elements, we can develop optical systems that deliver optimal performance for a wide range of applications.

Optical Layout

The layout of an optical system is typically determined by the application requirements, such as object and image distances, numerical aperture, and the wavelength of light.

Large Systems Capability, With Agile Team

Design Process

Several advanced software tools, such as Zemax and Code V, are available to assist in the optical layout and design process. These tools allow designers to model and simulate the behavior of optical systems, enabling them to optimize design parameters and achieve the desired performance. By leveraging these tools, we can ensure that our optical systems are precisely tailored to meet the unique requirements of each application.

Mechanical Design Considerations

The mechanical design maintains alignments. This involves selecting materials that can withstand thermal expansion, vibration, and shock. By carefully considering mechanical factors, designers can develop optical systems that are robust, reliable, and capable of delivering in a variety of conditions.

Electronics Integration

Modular Open Systems Architecture (MOSA) plays a vital role in electro-optics by enabling flexible and scalable integration. It standardizes interfaces and design, allowing easy upgrades and replacements as new technologies emerge. With MOSA, you can quickly adapt to changing mission requirements, reducing the risks of obsolescence and lowering long-term maintenance costs.

Testing

Verifying a design to requirements is key. This involves measuring various optical parameters, such as resolution and distortion. Several test methods are available, including interferometry and imaging, and the method depends on the specific parameter or requirement.

Experience Program Management

What differentiates Clear Align is our program management expertise, extending from the initial design phase to prototype development and full-rate series production.

Optical engineering plays a crucial role in managing complex optical projects, ensuring precision and efficiency throughout the process.

Advanced Environmental and Optical Testing

Environmental Stress Screening and testing equipment ensures we meet all specified requirements. This testing involves a series of evaluations of components, lenses, and complete systems based on military standards to verify the durability, reliability, and functionality of the solutions.

Clear Align offers the expertise of a large prime contractor with the agility and responsiveness of a small business partner. We bring value to our customers through integrated optical solutions.

Industry Applications and Best Practices

Optics is integral to a wide range of industries, each with unique requirements and challenges. From biophotonics and life sciences to semiconductor equipment and defense applications, the integration of high-quality optical components is crucial for achieving optimal performance. Understanding the specific needs of each industry and following best practices for system integration can significantly enhance the reliability and efficiency of optical solutions.

Biophotonics and Life Sciences

Biophotonics and life sciences are rapidly evolving fields that heavily rely on advanced optics for various applications. These systems are essential for detecting and analyzing biological samples, diagnosing diseases, and developing new treatments. The integration of high-quality optical components and systems is vital to ensure accurate and reliable results in these critical applications.

In biophotonics and life sciences, optical systems are commonly used in:

-

Microscopy: Optical systems magnify and analyze biological samples, allowing researchers to study the structure and behavior of cells and tissues in detail.

-

Spectroscopy: These systems analyze the interaction between light and biological samples, providing valuable information on the chemical composition and structure of the samples.

-

Imaging: High-resolution optical imaging systems capture detailed images of biological samples, enabling researchers to observe the morphology and behavior of cells and tissues.

To achieve optimal performance in biophotonics and life sciences applications, it is essential to follow best practices for optical system integration. This includes selecting high-quality optical components that meet the specific requirements of the application, ensuring proper alignment and calibration of the system, and using advanced optical design software to simulate and optimize performance. Collaborating with experienced optical engineers and researchers is also crucial to ensure that the system is properly integrated and optimized for the specific application.

Best Practices for Optical Systems Integration

Integrating optical systems requires a meticulous approach to ensure that the final product meets the desired performance and reliability standards. Here are some best practices to follow:

-

Define Clear Requirements: Clearly outline the requirements of the optical system, including performance metrics, size, weight, and power consumption. This helps guide the design process and ensures that the final system meets the specific needs of the application.

-

Select High-Quality Components: Choose optical components that are of high quality and suitable for the application. This includes considering factors such as material properties, optical performance, and environmental durability.

-

Ensure Proper Alignment and Calibration: Proper alignment and calibration of the optical system are crucial to minimize errors and optimize performance. This involves precise positioning of optical components and regular calibration to maintain accuracy.

-

Use Advanced Optical Design Software: Leverage advanced optical design software to model and simulate the behavior of the optical system. This allows for optimization of design parameters and ensures that the system meets the desired performance criteria.

-

Collaborate with Experienced Engineers: Work with experienced optical engineers and researchers to ensure that the system is properly integrated and optimized. Their expertise can help identify potential issues and provide solutions to enhance system performance.

Benefits of a Partnership

An partner offers a comprehensive approach to high-performance optical systems, from design to integration. With access to diverse materials, they select the best options for your needs, reducing time-to-market while delivering reliability.

Partnering with an Optical System Integrator

Partnering with an experienced optical integrator can provide advanced development and integration and reduce risk. An integrator brings skills in optical design, engineering, and production.

When selecting an optical system integrator, consider the following factors:

-

Experience: Look for an integrator with a proven track record in developing for new applications. Their experience can provide valuable insights and ensure your program hits all requirements.

-

Expertise: Ensure that the integrator has the knowledge in optical design, engineering, and fabrication. This includes knowledge of the latest technologies and best practices in the field.

-

Capabilities: Verify that the integrator has access to advanced optical components and systems, as well as the necessary integration and testing capabilities.

-

Communication: Effective communication is crucial for successful collaboration. Ensure that the integrator has good communication skills and can work closely with your team to understand and meet your requirements.

By partnering with an experienced integrator, you can ensure that your product is integrated and optimized for your application. This results in improved performance, reliability, and cost-effectiveness, ultimately enhancing the success of your project.